Qingdao Beisu Machinery Co., Ltd.

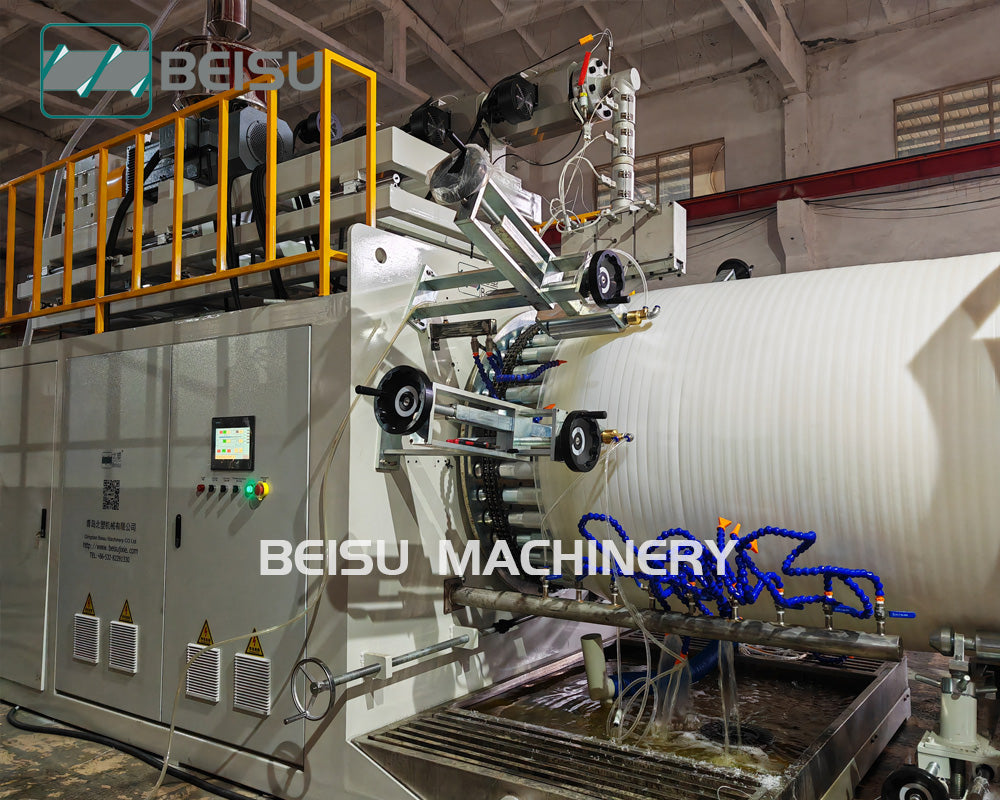

HDPE Sprial Solid Wall Pipe Production Line

HDPE Sprial Solid Wall Pipe Production Line

HDPE Sprial Solid Wall Pipe Production Line

The production line is used for producing HDPE spiral solid wall pipe. The pipe is used as pre-insulated jacket, water sewage pipe.Also it can produce plastic pipe socket.The thickness of the tube can be adjusted by adjusting the thickness and distance of the sheet. The operation is flexible and simple, and tubes of different thickness and diameter can be produced at will.

1.Single screw extruder

2.Forming Machine

3. PE sheet mould

4.Cutting Machine

5.Stacker

Products Description

Jacking pipe, also known as flexible sealed self-locking interface polyethylene winding solid wall drainage pipe/replacement pipe/replacement pipe, is a new type of pipe for trenchless construction, which can replace traditional cement jacking pipe, and is suitable for places where excavation is not allowed in densely built areas and construction is inconvenient; It can greatly save construction cost, repair and replace old pipes and separate rainwater and sewage.

The product has the following characteristics:

1. Sealed and self-locking, tight interface, no deformation, no leakage, anti-corrosion, acid resistance, anti-seismic, alkali resistance, no disconnection, and convenient construction;

2. The connection does not require hot melt docking equipment, and there is no internal flanging of the interface. The connection can also be carried out in the underground environment with water; 3. The length of the pipe joint is 0.5-1M, which is short and light, and can also be installed conveniently in a small space; 4. The overall level of pipeline connection is good, with good flexibility, and can adapt to uneven settlement;

|

No.

|

Diameters (mm)

|

|

No.

|

Diameters (mm)

|

|

SKRG800

|

200-800

|

SKRG1200

|

300 – 1200

|

|

|

Extruder

|

SJ75+SJ55

|

Extruder

|

SJ90+SJ65

|

|

|

Motor (kw)

|

45+18.5

|

Motor (kw)

|

75+30

|

|

|

Installed power (kw)

|

120

|

Installed power (kw)

|

200

|

|

|

Maximum capacity (kg/h)

|

400

|

Maximum capacity (kg/h)

|

550

|

|

|

Overall size (L×W×H) (m)

|

23.5×10×3.2

|

Overall size (L×W×H) (m)

|

24×10×3.5

|

|

No.

|

Diameters (mm)

|

|

No.

|

Diameters (mm)

|

|

SKRG1800

|

800 – 1800

|

SKRG2400

|

1200 – 2400

|

|

|

Extruder

|

SJ100+SJ75

|

Extruder

|

SJ120+SJ75

|

|

|

Motor (kw)

|

110+45

|

Motor (kw)

|

132+55

|

|

|

Installed power (kw)

|

300

|

Installed power (kw)

|

400

|

|

|

Maximum capacity (kg/h)

|

650

|

Maximum capacity (kg/h)

|

750

|

|

|

Overall size (L×W×H) (m)

|

24.5×11×5

|

Overall size (L×W×H) (m)

|

32×16×6

|

|

No.

|

Diameters (mm)

|

|

|

|

|

SKRG3000

|

1800 – 3000

|

|

||

|

Extruder

|

SJ150+SJ90

|

|

||

|

Motor (kw)

|

200+90

|

|

||

|

Installed power (kw)

|

600

|

|

||

|

Maximum capacity (kg/h)

|

900

|

|

||

|

Overall size (L×W×H) (m)

|

32×15×8

|

|

||